HMI is changing the way several industries are run now. It is a technology that automates several fields and improves productivity and efficiency on many levels. The merging of humans and machines through HMI is simply the next norm in industrial automation.

Interested in finding out more about HMI? Read on to get a general overview of this technology. Also, we’ll introduce STONE HMI displays and why they’re among the leaders in HMI technology worldwide.

Defining what HMI is

HMI stands for Human Machine Interface. It consists of a dashboard allowing a person to manipulate and interact with a system, device, or machine. HMI is often regarded as the merger of humans and machines for better automation efficiency.

HMI is also known as:

- Operator Interface Terminal (OIT)

- Man-Machine Interface (MMI)

- Local Operator Interface (LOI)

- Operator Terminal (OT)

The HMI presents visual information regarding a system to the user. The person, in turn, can operate and control the process by directly interacting with the machine using HMI software. Touch screens are often used together with HMI software for this system.

Information regarding industrial operating systems is displayed on an HMI screen through a Graphical User Interface (GUI). Icons, pictures, colors, and sounds can all be programmed to represent various operating conditions. The visual format allows users to easily interact with data needed to automate systems.

Some HMI systems also use other methods to exchange information between the human user and the machine. These methods may include speech recognition and motion sensors, among others.

Technically speaking, HMI can be used to denote all kinds of screens and systems allowing users to interact with any device. However, HMI is typically used in an industrial process context.

Three Main Types of HMI

There are several types of HMI systems. However, we’ll focus on the three main ones used in industrial operations: pushbutton replacer, data handler, and overseer HMI.

1. Pushbutton Replacer

This HMI type consists of a central control panel with several buttons. Each of the buttons performs a specific function. A pushbutton replacer allows important machine commands to be centralized in one location. Several factories use pushbutton replacers to manage the operations of different machines.

2. Data Handler

Data handlers consist of huge touch-capable HMI screens where visual representations, graphs, and production summaries can all be visible. This HMI type is used for harvesting or gathering data from the various machines connected to it. The data can be printed out or sent to a hard drive, depending on the user’s needs.

3. Overseer

Overseer HMI runs on the Windows operating system. It uses a TFT LCD touch screen to display a graphical user interface. This interface is then manipulated by the user to operate, control, and manage the machines connected to the HMI. Overseer HMIs are also equipped with plenty of Ethernet ports.

Most applications requiring Manufacturing Execution Systems (MES) or Supervisory Control and Data Acquisition (SCADA) benefit the most from overseer HMIs.

The Technologies Behind HMI

HMI operates based on a systematic network of hardware and software components.

Hardware Components

Computers and hardwired devices make up the bulk of hardware used in an HMI system. They are linked together so that operators can determine various process changes in their workflow and respond to them accordingly. Most of the computers and devices use touch screens where the user can view and manipulate processes in the system dashboard.

Capacitive touch screens allow operators to swipe and tap the HMI machines using their fingers in response to changes in process operations. Some industries use resistive touch screens in their HMI machines, though. This may require the use of styluses or more powerful finger touches to interact with the devices.

Other technologies such as voice control, gesture recognition, and eye tracking are also used in conjunction with touch screen computers and devices.

Hardware components serve as both input and output devices. Touch screens, for instance, allow a user to see operational changes (output) and directly interact with the device to manipulate his workflow’s operations (input).

Software Components

Special HMI software is programmed into the devices. This software typically uses Graphical User Interfaces (GUIs) to create dashboards for controlling various industrial operations.

Furthermore, advanced HMI software often consists of various techniques and technologies. Programs used in HMI devices may have a combination of the following:

- Machine Learning

- Natural Language Processing

- Virtual Reality

- Augmented Reality

- Internet of Things

These technological advances help ensure that machines can interpret human signals properly and vice versa.

Technology Behind Touch Screen HMI

Touch screens play a huge part in most industrial HMI systems in any field. From production plants to medical settings, touch screens are predominantly used to automate several tasks and ensure efficiency at work. So, how does HMI work in touch screens?

TFT LCD touchscreens are commonly used in industrial HMI settings. These touch screens are either capacitive or resistive. Either way, they display information through a graphical user interface. Such screens then collect information from the user by converting tactile signals from the user’s finger or stylus into electronic ones. The signals are then sent to a microprocessor who interprets them and directs the device to perform the needed action.

Pros and Cons of an HMI System

HMI systems have their advantages and disadvantages. Let’s enumerate them here:

Pros

- Improves overall communication within the facility

- Allows close monitoring of operational processes

- Lets an operator initiate quick responses to smoothen out the workflow (as a response to machine alarming, for instance)

- Reduces operational costs by eliminating the need for extra machines, cables, consoles, panels, indicator lights, and other monitoring equipment

- Allows for an overall easier plant management

- Opens up better applications when connected to advanced technologies such as the Internet of Things

- Enables more work to be accomplished in lesser time

- A cost-effective system in the long run

- Suitable for both simple and complex tasks

- New operators can easily understand the graphical nature of the HMI system

Cons

- Security may be prone to hacking if the HMI system is connected to the Internet

- Poor interface design may cause problems with performance and interaction between the machine and the operators

- More expensive to implement initially; needs careful deliberation to determine the right HMI type for the business to avoid huge losses

Industries Using HMI

These are the most common industries using HMI systems:

- Food and beverage processing

- Mining operations

- Oil and gas industries

- Transportation sector

- Pharmaceutical manufacturing

- Healthcare and patient monitoring in hospitals and

- Water and wastewater plants

- Energy and power sector

- Robotics applications

- Supervisory management using SCADA systems

- Automobile manufacturing

As you can see, HMI systems are prevalent in industries requiring multiple large machines and strict control environments. However, smaller HMI systems can also be used for small-scale industries for better work efficiency.

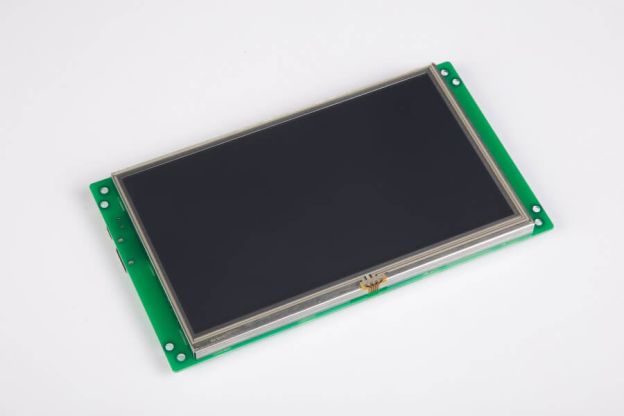

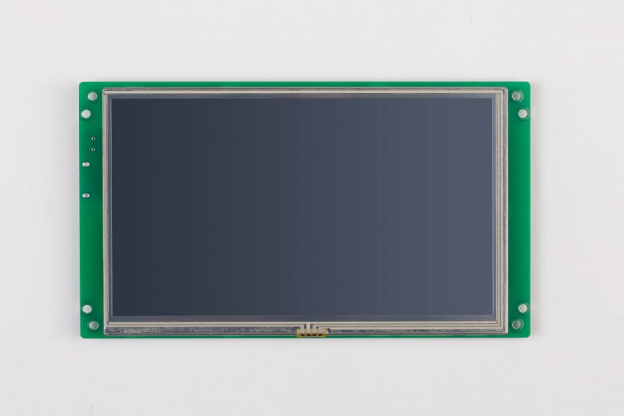

Introducing STONE HMI Display

STONE is China’s leading manufacturer of intelligent HMI display solutions. STONE is in the display solutions business for 14 years and has a wide range of international clients including Siemens, Bosch, and General Electric.

The company creates TFT LCD modules with touch screen capability suited for civil, advanced, and industrial uses. The STONE Industrial Type screen panels are the most popular products used for heavy-duty industrial systems. These screens feature:

- An industrial-grade TFT LCD panel

- CORTEX M4 CPU

- Touch panels capable of either resistive or capacitive technology

- LCD drivers

- Flash memory of 128M, expandable to 1GB

- High-resolution capability at 240P-768P, with a 65K (16-bit) color

- Pixel spacing of 0.1905 mm x 0.0635 mm (HxV)

- Touch screen Industrial Level RTP/CTP/NTP

Industrial-type screens can be used in ruggedized applications and fields with humid, high-temperature, and high-vibration working conditions. STONE’s industrial TFT LCD screens can be loaded with HMI software and connected with a smart system to create an overall industrial HMI solution.

Why Use STONE HMI Display Solutions?

Many clients looking for quality HMI display solutions head to STONE Technologies for their needs. That’s because STONE HMI display solutions offer the following benefits:

- Customizable service to fit your individual needs

- Products are durable, reliable, and withstand extremely harsh environmental conditions

- Professional technical support available in the forms of troubleshooting services, software training, and demo project making

- An unlimited warranty policy where the company replaces your STONE HMI display product if it has any damages or product failures – all for free

- STONE TOOL Box – a dedicated Graphical User Interface (GUI) software available for free download and use from its website

- Offers competitive yet affordable prices for their various HMI products

- Low minimum order quantity

- A lead time of only 14 days from date of product confirmation

- Responsive customer support readily available in English

STONE has been operating for 14 years. As such, the company continues to upgrade its HMI display solutions to reflect current technologies and trends. So, if you partner with STONE for your HMI needs, rest assured you’ll get only the latest TFT LCD modules paired with up-to-date smart technologies.

STONE also has top-of-the-line assemblies and production factories. These facilities are compliant with several regulatory bodies and have been awarded the following certifications:

- ISO9001

- ROHS Certification

- FC Certification

- CE Certification

All of these certifications guarantee that you’ll get only the finest HMI display products needed to complete your HMI ecosystem.

Conclusion

Human Machine Interface (HMI) is here to stay, and for good reason. Several industries around the globe have been using HMI systems paired with advanced technology such as the Internet of Things (IoT) for managing their daily operations. HMI allows for streamlined work, efficient plant monitoring, and seamless interactions between humans, machines, and fellow humans.

STONE Technologies is a leading global manufacturer of HMI Display Solutions. The company takes pride in its high-quality TFT LCD screens that can be used to complete any HMI ecosystem. With STONE, rest assured you’ll get top-notch display solutions and excellent customer service, all for a highly competitive yet affordable price tag.

Comments

Post a Comment